Cold Extrusion Hydraulic Power Press Machine 200T

Basic Info

Model No.: Yz61

Product Description

Cold extrusion is to place the metal blank in a cold extrusion cavity, and apply a pressure to the blank through a fixed punch on the press at room temperature to plastically deform the metal blank to produce a part processing method. At present, China has been able to cold-extrude metals such as lead, tin, aluminum, copper, zinc and their alloys, low carbon steel, medium carbon steel, tool steel, low alloy steel and stainless steel, even for bearing steel and high carbon. Aluminum alloy tool steel, high speed steel, etc. can also be cold extruded with a certain amount of deformation. In terms of extrusion equipment, China has the ability to design and manufacture tonnage extrusion presses at all levels. In addition to the use of general mechanical presses, hydraulic presses, and cold extrusion presses, it has also successfully used cold presses with friction presses and high-speed high-energy equipment.

Extrusion is a process for forcing a plastic flow of gold chips, through the gap between the punch and the die or the die exit, to make a part of a hollow or section having a smaller cross section than the blank. If the blank is extruded without heating, it is called cold extrusion. Cold extrusion is one of the processing techniques for chipless and less chip parts, so it is an advanced process in plastic processing of gold chips. If the blank is heated to a temperature below the recrystallization temperature for extrusion, it is called warm extrusion. Warm extrusion still has the advantage of less chipping.

Back extrusion

When back-squeezing, the flow direction of the metal is opposite to the direction of movement of the punch. Back-squeezing can obtain cups of various shapes.

Folded composite extrusion

When squeezed, part of the metal flows in the same direction as the punch, while the Other part flows in the opposite direction to the punch. Composite extrusion can produce a variety of cup, rod, and barrel parts.

Folding radial extrusion

When extruded, the flow direction of the metal is perpendicular to the direction of motion of the punch. Radial extrusion can be divided into centripetal extrusion and centrifugal extrusion, and radial extrusion is used to manufacture helical gears, flower keyboards and the like.

Technical specs

| Model | Unit | Yz61-100T | Yz61-160T | Yz61-160TA | Yz61-200T | Yz61-200TA | Yz61-315T | Yz61-400T | Yz61-500T | Yz61-630T | Yz61-800T | Yz61-1000T | |

| Working pressure | Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | |

| Main cylinder | Nominal force | KN | 1000 | 1600 | 1600 | 2000 | 2000 | 3150 | 4000 | 5000 | 6300 | 8000 | 10000 |

| Return force | KN | 160 | 210 | 210 | 240 | 180 | 300 | 340 | 350 | 600 | 600 | 600 | |

| Stroke | mm | 220 | 220 | 500 | 220 | 500 | 220 | 220 | 500 | 500 | 500 | 500 | |

| Slider speed | Descent | mm/s | 120 | 120 | 200 | 120 | 200 | 110 | 120 | 200 | 200 | 200 | 200 |

| Pressing | mm/s | 6-15 | 4-10 | 7-16 | 3-10 | 8-20 | 5-12 | 5-12 | 8-20 | 8-20 | 8-20 | 8-20 | |

| Return | mm | 90 | 70 | 120 | 100 | 160 | 100 | 120 | 150 | 200 | 150 | 150 | |

| Ejection cylinder | Nominal force | KN | 200 | 200 | 200 | 200 | 200 | 200 | 350 | 380 | 500 | 500 | 1000 |

| Stroke | mm | 80 | 80 | 80 | 80 | 80 | 80 | 100 | 200 | 200 | 200 | 200 | |

| Dia of rod | mm | 50 | 50 | 50 | 50 | 50 | 50 | 70 | 80 | 90 | 90 | 140 | |

| Ejecting speed | Ejection | mm/s | 80 | 80 | 120 | 120 | 150 | 80 | 120 | 125 | 130 | 150 | 100 |

| Return | mm/s | 120 | 120 | 200 | 120 | 250 | 120 | 210 | 160 | 250 | 250 | 200 | |

| Open height | mm | 600 | 700 | 900 | 700 | 900 | 700 | 800 | 900 | 900 | 1000 | 1000 | |

| Table size | L-R | mm | 500 | 600 | 600 | 600 | 600 | 700 | 800 | 800 | 900 | 1000 | 1000 |

| F-B | mm | 500 | 600 | 600 | 600 | 600 | 700 | 800 | 800 | 900 | 1000 | 1000 | |

| Motor power | KW | 7.5 | 7.5 | 11 | 7.5 | 18.5 | 18.5 | 22 | 44 | 60 | 74 | 90 | |

TECHNICAL SUPPORT

- Technical support by phone, telemaintenance

- On-site repairs

- Custom maintenance and preventive service contracts

- Spare part services

- Performance improvement diagnosis

- Extrusion molding hydraulic press.

CUSTOMIZED ENGINEERING

One of ZHENGXI biggest assets lies in its ability to design and manufacture customized equipment. We are an industrial engineering company, certified ISO 9001 that designs and supplies forming & testing equipment, production lines, customized machines and turnkey plants for the world's largest industrial groups. Our engineers and technical designers are at your disposal to provide you the best customized engineering experience for:

- Project management

- Manufacturing process

- Mechanics

- Thermal engineering

- Hydraulics

- Automation & Robotics

- Extrusion molding hydraulic press.

TRAINING SERVICES

- Licensed trainer

- Operator and Maintenance technician training

- Customized training on customer request

RETROFIT SOLUTIONS

- Improving equipment efficiency

- Improving process efficiency

- Retrofit to ensure compliance with stringent safety standards

- Automation

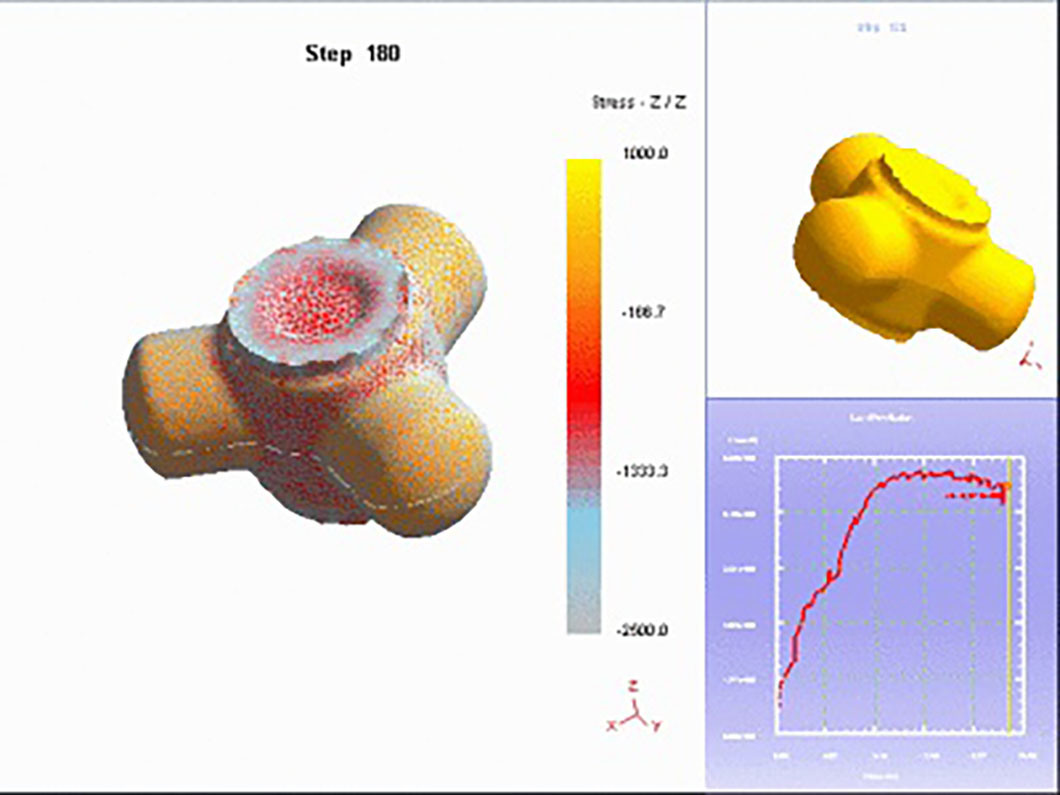

Schematic drawing of pressing process

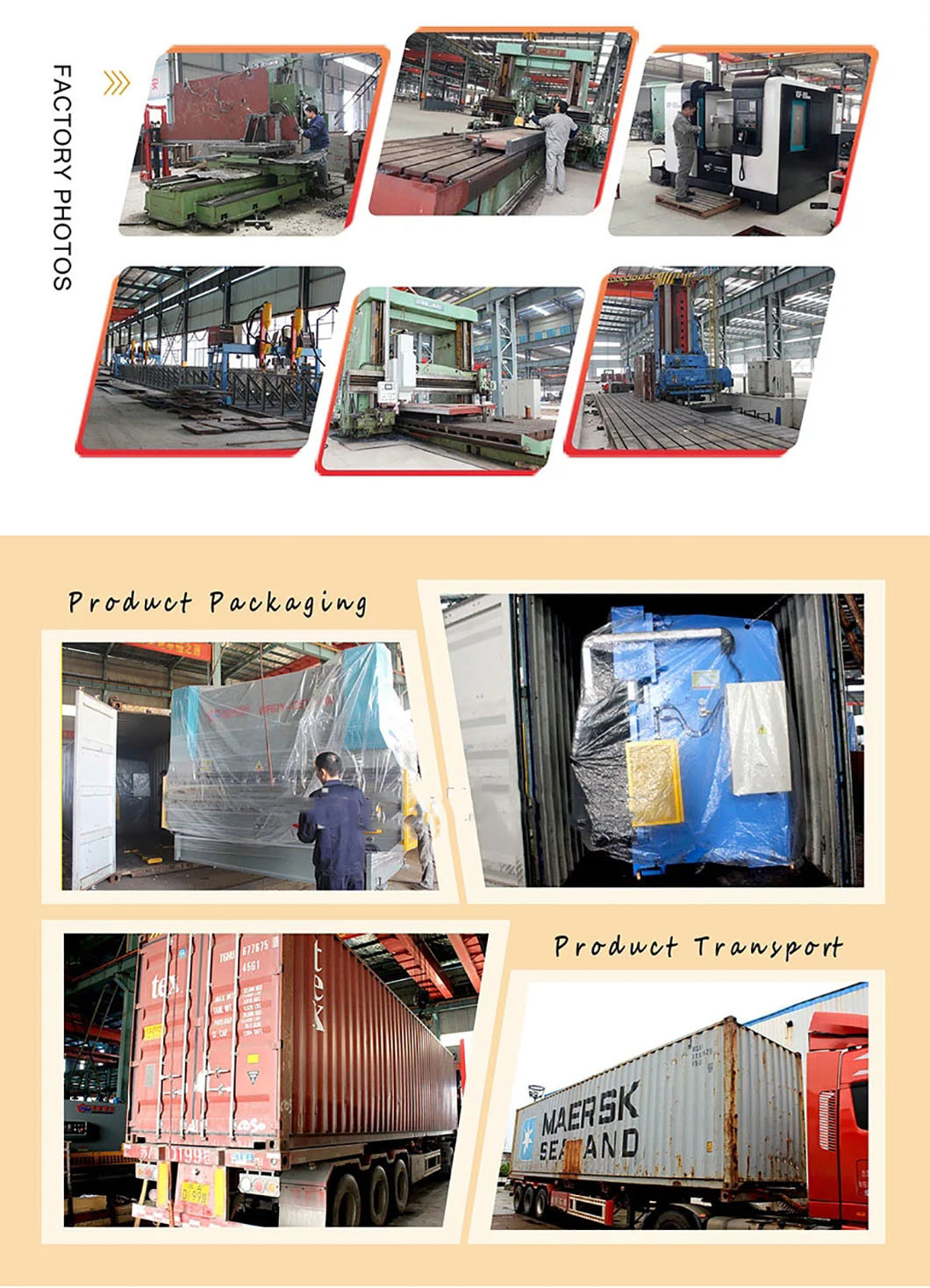

Workshop and packaging

Product application

Certificate

Contact way

Product Categories : Customization Hydraulic Press > Others Customization Hydraulic Press