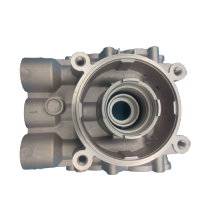

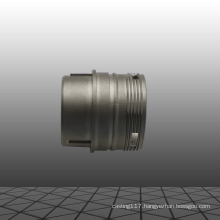

Aluminum die Casting part of Heat Exchanger

| Min. Order: | 2000 Piece/Pieces |

|---|

| Packaging: | carton, PE pallet |

|---|---|

| Productivity: | 5000/MONTH |

| Brand: | NONE |

| Transportation: | Ocean,Land,Air |

| Place of Origin: | NINGBO |

| Supply Ability: | 150000/MONTH |

| Certificate: | IATF16949:2016,ISO14001:2015,ISO45001:2018 |

| HS Code: | 7616991090 |

| Port: | NINGBO,SHANGHAI |

Basic Info

Model No.: BL031

Click on the follow link to find out more information: https://www.blcastings.com/machine-parts-housing/

Company Info

- Company Name: NINGBO ZHENHAI BOLANG METAL PRODUCT FACTORY

- Representative: LIU CHENGZHI

- Product/Service: Die Casting , Precision Machining , Precision Casting , Pressure Casting , High Precision CNC Machining , Ferrous Metal

- Capital (Million US $): 1000000 RMB

- Year Established: 2001

- Total Annual Sales Volume (Million US $): US$2.5 Million - US$5 Million

- Export Percentage: 91% - 100%

- Total Annual Purchase Volume (Million US $): Below US$1 Million

- No. of Production Lines: 3

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 1,000-3,000 square meters

- Factory Location: Guisi Industrial Zone, Luotuo Street, Zhenhai District,Ningbo,315206,China

- Contact Person: Mr. Ethan

- Tel: 86-0574-86556929

Email to this supplier

Premium Related Products

Other Products

Hot Products

custom made aluminum car spare partsbrass belt bucklecustom made Stainless Steel Pipe WeightHigh quality fashion home furniturealuminum 6061-t6 cnc milling machine partenclosure boxcustom made auto parts in turkeycustom made aluminum casting ring gear for cement mixerhigh quality wall mounted bottle openergear box housing for aluminum alloy die casting auto partsSupply of high quality titanium grip strength hand massage fitness equipmentFactory custom car motorcycles quality valve spring seatAluminum worm gear box deceleration chassisCustomize a variety of Automotive filter air conditioning filtercustom kinds of metal accessories and Mahjong machine cup holdersQuality hardware Lighting Parts LED aluminum heat sink parts