aluminum tube

Basic Info

Model No.: 6061

Product Description

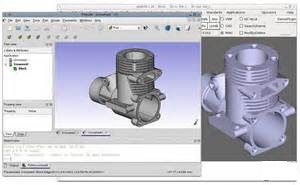

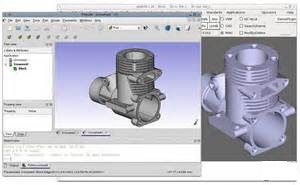

Product Description : 1. Raw Material (Aluminum ingot / Aluminium ingot): aluminum alloy ADC12, A360, A380.  2.Design to prototyping: (1)mould design according to Pro/E, Auto CAD, Solidwork,

2.Design to prototyping: (1)mould design according to Pro/E, Auto CAD, Solidwork,

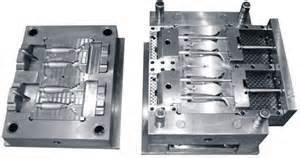

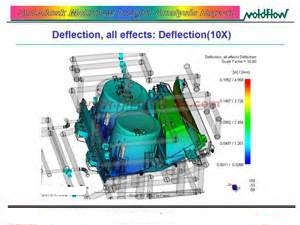

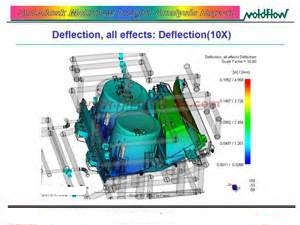

(2)Mould flow analysis.  Mould model will indicate : - Tentative gate and ejector pin location - Tentative parting line locations - A general idea of the configuration of the cavity, core, and any sliders needed. (3)Test mould, proofing.

Mould model will indicate : - Tentative gate and ejector pin location - Tentative parting line locations - A general idea of the configuration of the cavity, core, and any sliders needed. (3)Test mould, proofing.

(4)Deburring,Drilling,Post machining.

(5)Surface treatments: Polishing, painting, anodization, shot blasting, power coating, electrophoresis, zinc plating, black oxidation. (6)Quality Control

(5)Surface treatments: Polishing, painting, anodization, shot blasting, power coating, electrophoresis, zinc plating, black oxidation. (6)Quality Control

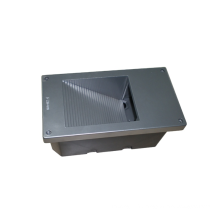

Aluminum Casting parts, Aluminum Alloy Casting, gravity die Casting, auto parts and components, air compressor, housing for power resistors, handles for switching power supplies, clips, Aluminum front panels, terminals, turning parts, fuse holders etc. A Manufacturer of die cast handles. Zinc & aluminum die castings, pneumatic fittings, die cast handles & automotive starter, electrical & tool housings. Die casting capabilities include tooling, drilling, tapping, facing, slotting & CNC turning. Industries served include electrical, automotive, aircraft, hardware, appliances, architectural, agricultural, communications, telecommunications & government defense.

Aluminum Casting parts, Aluminum Alloy Casting, gravity die Casting, auto parts and components, air compressor, housing for power resistors, handles for switching power supplies, clips, Aluminum front panels, terminals, turning parts, fuse holders etc. A Manufacturer of die cast handles. Zinc & aluminum die castings, pneumatic fittings, die cast handles & automotive starter, electrical & tool housings. Die casting capabilities include tooling, drilling, tapping, facing, slotting & CNC turning. Industries served include electrical, automotive, aircraft, hardware, appliances, architectural, agricultural, communications, telecommunications & government defense.

Contact us if you need more details on Aluminum Tube. We are ready to answer your questions on packaging, logistics, certification or any Other aspects about Aluminum Pipe、Extrusion Tube. If these products fail to match your need, please contact us and we would like to provide relevant information.

2.Design to prototyping: (1)mould design according to Pro/E, Auto CAD, Solidwork,

2.Design to prototyping: (1)mould design according to Pro/E, Auto CAD, Solidwork,

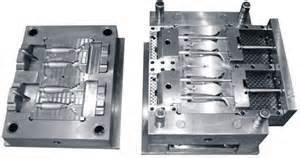

| 1.mould design | according to CAD file(IGES,STEP,PRT) |

| 2.mould material | mould frame:45#steel or ductile iron mould core:H13 |

| 3.suitble process | die casting |

| 4.suitble material | aluminum,zinc,copper |

| 5.suitble machine | 88-800ton hot chamber Die Casting machines |

| 6.mould life | 50000shots |

| 7.mould time | 35days finished mould |

Mould model will indicate : - Tentative gate and ejector pin location - Tentative parting line locations - A general idea of the configuration of the cavity, core, and any sliders needed. (3)Test mould, proofing.

Mould model will indicate : - Tentative gate and ejector pin location - Tentative parting line locations - A general idea of the configuration of the cavity, core, and any sliders needed. (3)Test mould, proofing.

| Picture | Machine |

| one set 800 ton hot chamber die casting machine. |

| two sets 500 ton hot chamber die casting machines. |

| two sets 280 ton hot chamber die casting machines |

| two sets 160 ton hot chamber die casting machines. |

| one set 88 ton hot chamber die casting machine. |

(5)Surface treatments: Polishing, painting, anodization, shot blasting, power coating, electrophoresis, zinc plating, black oxidation. (6)Quality Control

(5)Surface treatments: Polishing, painting, anodization, shot blasting, power coating, electrophoresis, zinc plating, black oxidation. (6)Quality Control

Aluminum Casting parts, Aluminum Alloy Casting, gravity die Casting, auto parts and components, air compressor, housing for power resistors, handles for switching power supplies, clips, Aluminum front panels, terminals, turning parts, fuse holders etc. A Manufacturer of die cast handles. Zinc & aluminum die castings, pneumatic fittings, die cast handles & automotive starter, electrical & tool housings. Die casting capabilities include tooling, drilling, tapping, facing, slotting & CNC turning. Industries served include electrical, automotive, aircraft, hardware, appliances, architectural, agricultural, communications, telecommunications & government defense.

Aluminum Casting parts, Aluminum Alloy Casting, gravity die Casting, auto parts and components, air compressor, housing for power resistors, handles for switching power supplies, clips, Aluminum front panels, terminals, turning parts, fuse holders etc. A Manufacturer of die cast handles. Zinc & aluminum die castings, pneumatic fittings, die cast handles & automotive starter, electrical & tool housings. Die casting capabilities include tooling, drilling, tapping, facing, slotting & CNC turning. Industries served include electrical, automotive, aircraft, hardware, appliances, architectural, agricultural, communications, telecommunications & government defense. | Die Casting Mould | Cavity | Single or multiple |

| Material | H13,DIEVAR,QDN,8407,2344V,TQ1,2343,SKD61, 45#steel,etc. | |

| Heat treatment | Hardened, Nitriding | |

| Hardness | HRC50~55 | |

| Mould features | Advanced design, Logical structure, High precision, Qualified materials, Long lifetime, Short delivery time. | |

| Die casting product | Material | Aluminum alloy,A360, A380, A383, AlSi10Mg, AlSi9Cu3, ADC3, ADC6, ADC12, ZL104, ZL107. |

| Process | Casting, Deburring, Machining, Surface Treatment, Packing. | |

| Surface treatment | High quality polishing, Chrome/nickek/Zinc(white, blue, yellow, black)plating, hot galvanized, painting, powder coating, Anodizing, electrophoresis, sandblasting and ect. | |

| Leadtime | 7-30 days | |

| Advantage | Company established | in 2003 |

| Software | Pro/E, Auto CAD, solid work 2001,CAXA,UG,CAD,CAM | |

| Machines | High, refined, sharp equipment, a more high-speed processing center, walking thread cuttings, precision machine sparks, large grinding machines, CNC engraving machines and 10PCS of die-casting machines ( range from 160 to 1250 Tons). | |

| Inspection equipment | Metal material metallographic analyzer, metal detection machine, coordinate measuring machine, large-scale aluminum material direct reading spectrometer, aluminum material hardness meter, X optical testing machine, tensile testing machine, used from mold manufacturing to samples test. | |

| R&D team | Plentiful experience and skillful technique on die casting | |

| Certifications | ISO9001:2008, TS16949 |

Product Categories : aluminum extrusion part

Premium Related Products

Other Products

Hot Products

custom made aluminum car spare partsbrass belt bucklecustom made Stainless Steel Pipe WeightHigh quality fashion home furniturealuminum 6061-t6 cnc milling machine partenclosure boxcustom made auto parts in turkeycustom made aluminum casting ring gear for cement mixerhigh quality wall mounted bottle openergear box housing for aluminum alloy die casting auto partsSupply of high quality titanium grip strength hand massage fitness equipmentFactory custom car motorcycles quality valve spring seatAluminum worm gear box deceleration chassisCustomize a variety of Automotive filter air conditioning filtercustom kinds of metal accessories and Mahjong machine cup holdersQuality hardware Lighting Parts LED aluminum heat sink parts